Not all sails are amazing voyages of wonder and self-discovery. There are high notes, and there are low notes.

We technically sailed on October 3, and I’ve been unable to say anything remarkable about it. The remnants of various tropical storms and other volatile weather have prevented us from sailing since, and without the mounting pressure of having the next log entry to get out, I guess I just let it go. In the intervening time, I’ve lost track of what we even did. In these situations, I often go to the photos to remind myself, but we barely took any.

Apparently, we saw a Block Island 40. That’s a lot of boat for Barnegat Bay, which I suppose is why I took a picture of it?

We also saw a Pearson 34 that I recognized from the marina across the way. I remember that we hunted them down somewhere south of BI and they tacked around before I had the opportunity to pass them. I gave them a brief head start in that direction so as to not tack on top of them, then we came about and easily passed them going north.

I also remember that the following boat tested my resolve as the stand-on vessel on starboard tack when she sailed directly at us for a long time on port tack before dodging us at the last moment. I guess they run into a lot of stuff, since they were ever-cautiously sailing around with their fenders out.

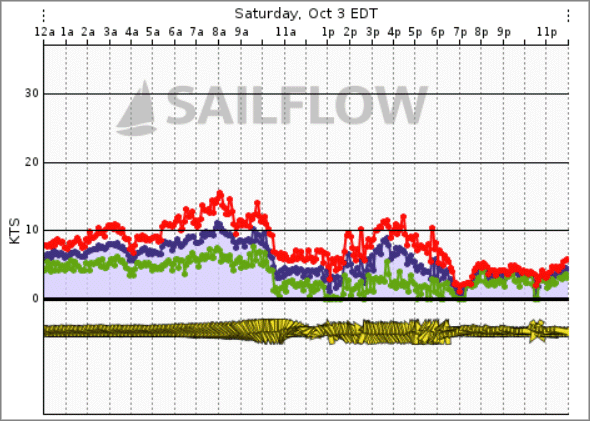

We couldn’t even remember the wind speed. I guessed that it was 10kts, and Jenn said that it was much less. Fortunately, we can look this up, and we were possibly both right at different times of day. I do recall that I broke out the tiller pilot for a while, just as a test and since there wasn’t much else going on.

Regardless of whatever happened or didn’t happen that day, the brief hiatus from sailing did allow me to complete a project that I’ve been working on on-and-off since…I don’t know, May-ish? Time has no meaning. But, speaking of low notes, I made a bass guitar.

Despite having built a quarantine ukulele earlier this year, I still feel like I’m out of practice at making instruments, so I bought a kit for a bass in the style of a Fender Precision. Then I saw the contents of that kit, and immediately discarded the body, pickup, electronics, knobs, bridge, pickguard, nut, and strap pegs, which left…uh, not much from the kit.

The kit body was supposedly alder, which (along with ash) is one of the classic woods for a Fender P-bass, but this one was made out of like 5 different scraps glued together and didn’t really look or feel like any alder that I’ve ever handled. Wood names are a mess, and I’m sure it’s something in the alder family, but not Alnus rubra or one of the other North American species that I’m familiar with. It probably would have been fine if I wanted to put opaque paint on it, but I’ve never wanted to do such a thing. Instead I bought a blank of Spanish cedar.

Spanish cedar is, of course, neither Spanish nor cedar. It is Cedrela odorata, more closely related to mahogany, but is softer and lighter in both weight and color than a true mahogany (let’s say Swietenia macrophylla since I’m tossing around so much Latin). It is used in a lot in classical and flamenco guitars, so it’s not without precedent to use it in an instrument, but I don’t think it’s very popular for solid bodies. I thought I’d give it a try anyway for something different.

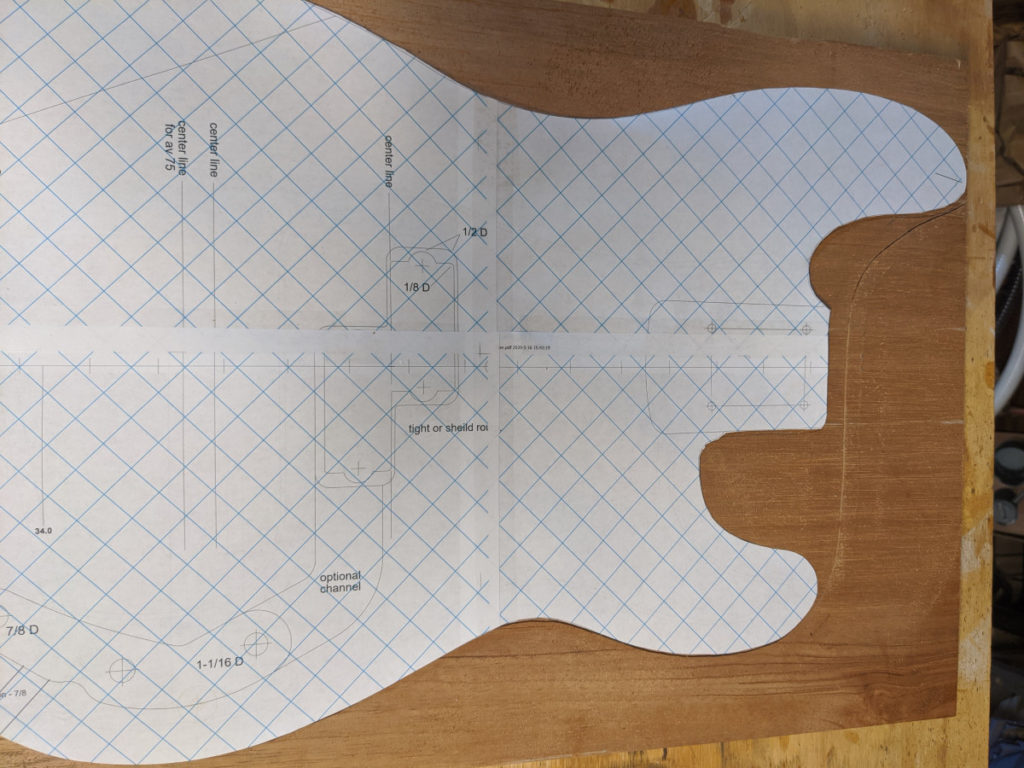

I found a plan for a P-bass online and attempted to adapt it for my use.

It was in a PDF, and I couldn’t make my cheeseball PDF software print it out in any sort of coherent way over four sheets of 8.5 x 11″, so this turned into a whole sub-odyssey for turning a PDF into an SVG and attempting to draw an alignment grid on it with free, incomprehensible vector graphics software. I got close enough.

I then went after it with an angle grinder, rasps, files, and eventually scrapers to put the body contours in.

Next was routing the top to create the cavities for the pickup, electronics, and the neck pocket. This is always a stressful operation for me. I had intended to use the routing on the existing body as a guide to make a template, but it wasn’t quite right for my replacement pickguard, so instead of just sticking some wood to it and using a flush trim bit to copy it, I could use it only for inspiration. I wound up making my own custom template with a scroll saw and a lot of fitting with a file. Fortunately, on this style of body, the sins of imperfect cuts are easily hidden as long as you don’t do anything egregious. I went slowly and only took shallow passes with the plunge router, even though the Spanish cedar cut easily.

The rout for the neck pocket was copied directly from the kit body—I just needed to be careful to position it so that the strings would terminate in the correct place on the body. That cut has less room for error than the one for the pickup and wiring, since it has to make a good mechanical fit with the neck and be exactly straight in reference to the instrument’s centerline. There’s a little forgiveness with the positioning of it on an electric instrument, since the saddles on the bridge move and can be fine-tuned after the fact, but it still needs to be close enough to be within their range of travel.

With that out of the way, I sanded both the body and the neck for what seemed like days. The finish that I use (Tru-oil) is extremely thin, and is at its best when the wood is practically polished, so I take it at least up to 320 grit, and in this case more, since 400 seemed to actually be doing something on the maple neck.

I then proceeded to finishing. I finish the neck and body separately, and since my shop is in the basement, I hang them from crap sticking out of the exposed joists to dry. A few days in, I hung the neck above my bench as I always do, and the crap sticking out of the joist fell out. The neck fell directly on the body and dented it.

The neck was mostly fine (except for that coat of finish getting completely messed up), which was surprising since I guess it bounced? It definitely made multiple dents in the body. This was disappointing, but I wasn’t about to abandon ship at that point. I still had the offcuts from when I cut the body out, and considered taking the wood from the adjoining part and making a patch that would pretty closely match the grain on the edge. Before I went through all that trouble though, I thought maybe I could steam them out.

Thanks to permanent press, I was forced to embark on a grid search for my clothes iron. Oddly, I have an iron that is dedicated to luthiery, which I ruined for clothing many years ago while trying to scavenge a broken Martin LX1 “Little Martin” for parts. They don’t make irons like they used to, and they’re incapable of being cleaned (or deodorized) once they’ve been used to melt adhesives and whatever black ichor was giving the fingerboard its tenuous appearance of ebony. I could not find that iron, but I did find a different iron, and proceeded to iron the bass with a damp washcloth, almost completely removing the dent.

This did mean that I needed to re-sand and push back the finishing schedule, but it was easier than making a patch, and eh, it’s on the back.

Once I got it finished, I was able to line the cavity with copper foil to block electrical interference. I love the look of the copper when it’s fresh.

It goes on the underside of the pickguard too.

Then it was just a matter of bolting the neck on, installing the hardware, and stringing it up. I’ve actually had it together for a while, but I wanted to let it settle in a little before I did the final setup. Over the last couple weekends I got some flatwound strings, cut a new nut from a bone blank, and finally dialed in the relief, action, and intonation. I play bass about 1% as much as guitar, and I barely play guitar, so I had to rely on a lot of info from the web on how it’s “supposed” to be set up, but I think I got it to a good place, at least for now. The neck seems huge compared to the Fender Jazz Bass that I have on permanent loan, but it hasn’t been annoying so far, and kind of reinforces that I’m not playing standard guitar.

It also sounds exactly like I expected it to sound, with the P-style pickup, flats, and a soft body, it thumps. I’m glad I sprang for the Seymour Duncan. Here she is, lounging on my couch.

Here’s to the low notes.