I celebrated the autumnal equinox with some maintenance.

I accept that maintenance is a part of owning a boat. On the other hand, my real interest is in sailing, and I’m always trying to walk the line of doing the least possible amount of maintenance that will allow me to sail the boat without incident. That may seem obvious, but I know plenty of people whose real hobby seems to be boat maintenance, where actual sailing is merely an abstract potential. That’s fine if that’s your jam, and I’m sure that the decade-long experiments to find the platonic ideal of marine sealants or the apotheosis of backup auxiliary AIS transponders is interesting and valuable to someone. I’m much more likely to ask myself “Can I technically sail with no functional windows?” or “I can still sail if all my teak turns to sharp gray dust, right?” And the answer is usually yes.

There is always a reckoning though, and I finally took some time to address a few things.

Whale Flipper Pump

The sink pump in my head has been non-functional for some time. This is a manual pump, made by Whale, that pulls water from my freshwater tank and theoretically squirts it into the sink in the head. I took it home several weeks ago and partially disassembled it to see if there was anything obviously wrong, but I didn’t see anything obviously awry. I figured I could bring it back with a service kit, having run into something similar with the foot-operated Whale Gusher Pump in my galley: there are a bunch of rubber parts in these that just have a finite lifespan.

I got Service Kit AK0405, which is the one that comes with all of the rubber bits. Not to be confused with AS0406, the Overhaul Kit that comes with mostly hard plastic bits. My kit came with instructions, but they were the instructions to drill a hole in your counter to install it, which I did not need since it has been installed for some time. There was no indication of how to take it apart or what to do with all of the things in the kit, which would have been more useful, especially considering that it was surprisingly difficult to break down into its principal components. I probably didn’t need to take it as far as I did just to install the serviceable parts, but I couldn’t clean it adequately with it only partially disassembled, and it really needed to be cleaned.

I went after it with a pair of forceps and a claw hammer. I was mostly concerned about breaking something in the process, and had to use an increasingly elaborate set of vises, clamps, and cauls to try to hold and support it so that I could hammer pins out without destroying it in the process. I couldn’t get one of the gaskets off (the one that would be a “piston ring” if it was an engine component) and pulled out my pocket knife to teach it a lesson. It slipped, and I made one of those cuts in my finger where you have just enough time to look at it and say “Oh, that’s going to be bad” before a little red dot appears at the end of each severed capillary, then blood starts shooting out.

I took a moment away from repairing the pump to repair myself and then continued on. I eventually got it back together, clean, and with the new rubber doodads in place. It worked, and I went to the shore the next day to reinstall it.

Bow Light

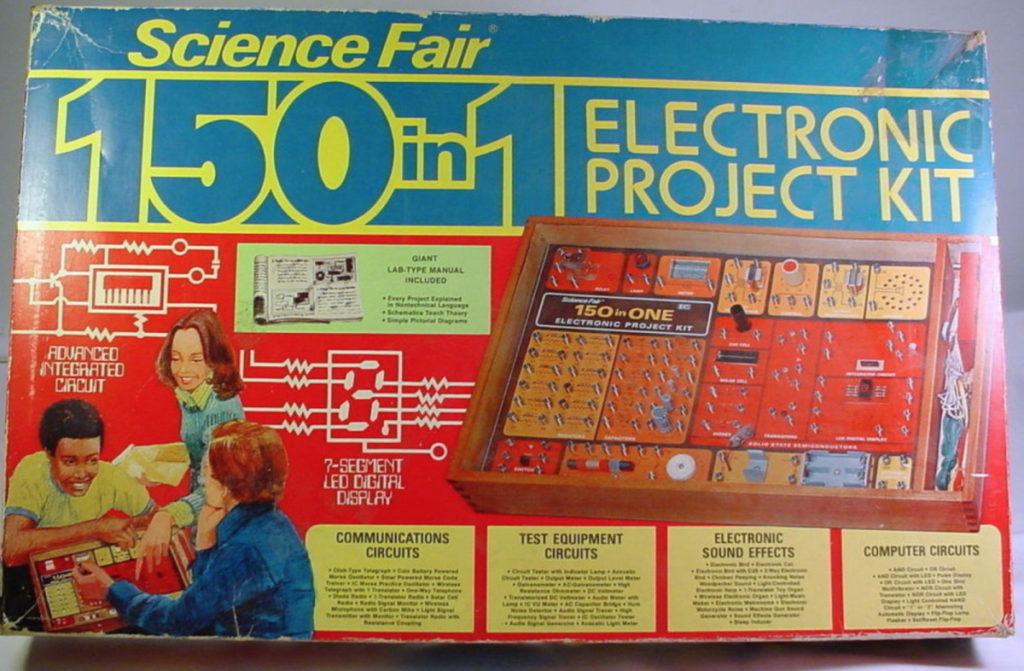

At the boat, the pump went in easily and worked when connected to my freshwater system. I then attempted to answer the age old question of “How many sailors does it take to screw in a lightbulb?” My bow light has been exhibiting my favorite sort of problem: intermittent. I could understand if it either worked or didn’t work, but working “occasionally” is harder to accept. It’s a battery, a switch, and a lightbulb…it’s about the dumbest possible circuit. It’s what you put together in the first minute of playing with your 150-in-1 electronics kit on Christmas morning.

Which is why my meter readings made no sense. I’m completely onboard with Buddhism’s concept of The Middle Path, but not when it comes to electricity. Valid readings would have included 0V or something north of 12V, but not the 5V that I was seeing. I can only assume that the wire running from the electrical panel to the pulpit (which is admittedly a pretty long run) has corroded to the point where it has become a giant resistor. I did find a mysterious “third wire” in there that was reading well over 12V though, so I wired it up with that, and the light came on.

I turned off the power at the main panel, pulled the lightbulb, and went to a certain occidental marine products store. I had a gift card burning a hole in my pocket, and even though their LED prices are genuinely absurd, I wanted to switch my bow light from incandescent to LED on credit. The world of marine LEDs is a mess, with the regulations, opinions, and [possible?] science in conflict. Some say that you can’t put a white LED behind the red and green lens in a bow light. Some say that you can if it’s a “warm white.” Some say you need actual red and green LEDs in there, which isn’t even an option for me given that there is only a single bulb in my fixture. Some say that it needs to be US Coast Guard approved, even though there are lots of things in the world that are way better than the published spec but have not bothered to go through the certification process. If that wasn’t enough, the sizes of the bulbs are barely standardized. I have what I believe is called a “festoon” bulb, which is a ludicrous name, and comes in sizes such as 28mm, 31mm, 39mm, 44mm, and can have pointed, dimpled, or possibly other ends on it. I found a kit from Dr. LED that came with a light and an assortment of optional end attachments (because who doesn’t want a “some assembly required” lightbulb?) that said in bold letters across the top of it “WARM WHITE.”

I drove back to the boat. I had pulled the boat forward in the slip so that I could reach the pulpit from the dock, which may or may not have actually made my life any easier, but allowed me to immediately install it. I got on the boat to turn on the power, then got off the boat to check it, and found the little LED modules glowing a bright red. I looked again at the packaging, and although it said “WARM WHITE” in bold letters at the top, below the blister pack there were small check boxes for red, green, and blue (?), and “red” was definitely checked. Thanks, Dr. LED. Not misleading at all, and it makes me question whether you’re even really a doctor.

I got back on the boat and turned off the running lights at the panel, then got off the boat to pull the bulb. It was still on. In approximately the same time that it took me to start bleeding after cutting myself the night before, I realized that the mysterious third wire is not on the switch for the running lights. It’s apparently always on when the main power is on. I realize that this is mostly my fault; I shouldn’t have just used a random wire, or should have at least considered whether it was on the same switch, but there’s seriously no reason for it to be there at all. There’s nothing else up there. I briefly tried to figure out where these wires come from or where they go, since they sort of appear out of nowhere in my anchor locker and the line to the pulpit is spliced in (poorly), but then I realized that they were all wrapped in furlongs of electrical tape, and I flashed back to previous electrical tape nightmares that filled me with a sort of sad rage. It was getting late, and all I could do was put it back the way it was, delivering (intermittently) an inadequate 5V to my stupid incandescent bow light. I’ll come back some other time and either pull new wire or figure out where the working-but-unswitched wire goes and use that, but I needed to move on.

Rig Tuning

The last time we sailed, I noticed that the leeward shrouds were completely slack and dangling when sailing upwind. I would expect them to have little tension in that situation because the mast is supposed to give a little bit, but I don’t think they’re supposed to be flapping, so I made a mental note to tune the rig.

This involves removing the pins in the turnbuckles at the bottom of each wire that supports the mast and adjusting the tension by holding the microscopic portion of “flat” on the wire’s terminal and rotating the body of the turnbuckle. I have a thing called a Loos Gauge—I actually have two, because my lower shrouds are the largest wire size that can be measured by the small gauge and my stays and upper shrouds are the smallest wire that can be measured with the large gauge—which is supposed to measure tension, but it is sufficiently unscientific looking that I only ever really treat it as a ballpark estimate, and as a relative measure rather than an absolute one. Still, I looked up the wire diameters and their breaking strength so that I could figure out 10-15% of it and translate that to the arbitrary number system on the gauge. I could have sworn that I had a notebook in my nav bag, but wound up doing the math on a paper plate, because everything I do has to be at least partially comically shitty.

It’s not that difficult, but it does require a lot of small adjustments and constant checking to make sure the measured tension hasn’t gone bonkers or that the mast hasn’t been pulled into some weird curve or S-shape. The largely vestigial side decks on a Catalina 27 at least make it uncomfortable. The main problem was that the equinox had passed, and the days just aren’t that long anymore. I was half operating by moonlight by the time that I was satisfied enough to start putting the pins back in.

The real test will be the next time we sail it and I see what it does on the water.