Time to replace the water pump.

As previously mentioned, after changing the impeller as part of routine spring maintenance, I noticed that water was shooting out of the back of my raw water pump. I assumed that it wasn’t supposed to do that, which was close to my complete knowledge of water pumps at the time. I have since learned far too much about them.

The engine in Fortuitous is a Beta 14, which is a Kubota diesel that has been modified for marine use. It has a closed cooling system full of antifreeze like a car engine, but on a car, the heat that the coolant absorbs is dissipated through a radiator. There’s no reasonable place for a radiator on a sailboat, and they never go fast enough for a radiator to get efficient, so the heat is instead dissipated through a heat exchanger, which runs the antifreeze through a series of tubes that are bathed in flowing water that is pumped up from whatever the boat is floating in. The pump that does that is the raw water pump, although in my case, it was diverting a great deal of raw water onto the floor of the engine bay.

Water pumps are driven either by a belt or directly from the internal workings of the engine. Mine is the latter. I contacted Beta, and although it’s possible to rebuild the pump and replace the seals, they recommended replacing the entire thing. After checking around with sailor friends and watching some pump rebuilding videos (which made it out to be a substantial hassle, not to mention that I’d be forever nervous that I somehow messed up a seal and was pumping water directly into the oily parts of my engine) I concurred and ordered one.

It also came with an O-ring and two blocks of metal that appeared to clip it to the engine, which seemed like an unnecessarily precarious way of attaching something that is connected directly to the cam (or whatever). I’m sure it’s fine. I feel the same way about the PATCO tracks that were obviously bolted to the sides of the Ben Franklin Bridge as an afterthought, but I guess they’re also still holding up. Sometimes I think that Legos may have made me overly cautious in this regard, because these designs would never fly in Lego form, but are apparently acceptable in bronze and bridges.

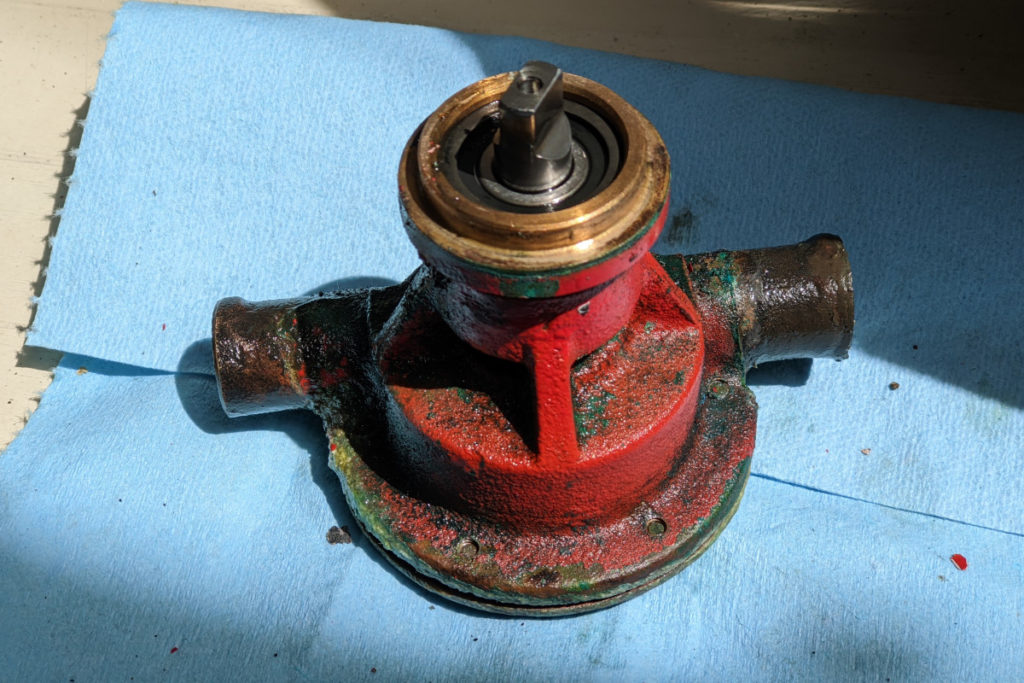

I continued to bother my sailing chums with endless questions about water pumps until the next sunny day, then went to the shore to replace it. This is the before pic. Notably, before I cleaned the engine:

It really needed a good cleaning, both for general tidiness, and because I didn’t want any junk to get inside the engine once I opened it to the outside world. I removed the belt and brushed most of the three-dimensional dirt off, then hit it with some engine cleaner.

In my mind, this was going to be so easy. I’d done the homework: remove two hose clamps, remove two bolts, bada bing, bada bolt..done. But as with all marine maintenance, everything is more annoying than anticipated. One minor technicality: there are no bolts. I was picturing bolts that would go into threaded holes in the engine, but there are fixed studs coming out of the engine and the clamps are held on with nuts. More importantly, because the nuts are deep down by the pointy part of the generally-cone-shaped pump, there wasn’t room to use a ratchet. Even a socket by itself didn’t have enough clearance. So I switched to normal analog wrenches, which are fine, but because of the other things sticking out of the engine, I could only use them at awkward angles that made it difficult to get them started. Once they were started, I could only turn the wrench about 15° before it ran into something else sticking out of the engine, so I had to manipulate it a couple dozen times to get the nut to turn one revolution. It could have been a lot worse (like if the pump wasn’t on the front of the engine) and it wasn’t anywhere near as bad as, say, replacing a portlight, but it did take me longer than I thought it would.

It looks dirty, but I think it’s just corrosion and flaked paint. There were some additional paint flakes from around where the parts joined, since it looks like the engine was painted with the pump in place, and I carefully cleaned them away. The nuts and other mounting hardware were also corroded, and I decided to run out and get new ones.

Traditionally, I would have gone to a local hardware store for this sort of thing, but it’s been closed for a while. In fact, they razed the building and built something there that looks like an East German grocery store. I decided to go to the big-box store of marine stuff, since it had been a while since I’d seen a novelty captain’s hat in person and was curious about the latest advances in bottle opener technology.

I wasn’t sure what size the nuts were, but I brought them with me to test fit them. The bins of stainless hardware at the store were well-stocked and the nuts threaded onto #12 bolts. I got a couple nyloc nuts, a couple standard nuts in case the nylocs were too tall, and washers. There were split lock washers on the old pump, but I don’t believe that they actually do anything and just got flat ones. I defer to NASA’s Fastener Design Manual on such questions, and they throw so much shade on split lock washers:

The lockwasher serves as a spring while the bolt is being tightened. However, the washer is normally flat by the time the bolt is fully torqued. At this time it is equivalent to a solid flat washer, and its locking ability is nonexistent. In summary, a lockwasher of this type is useless for locking.

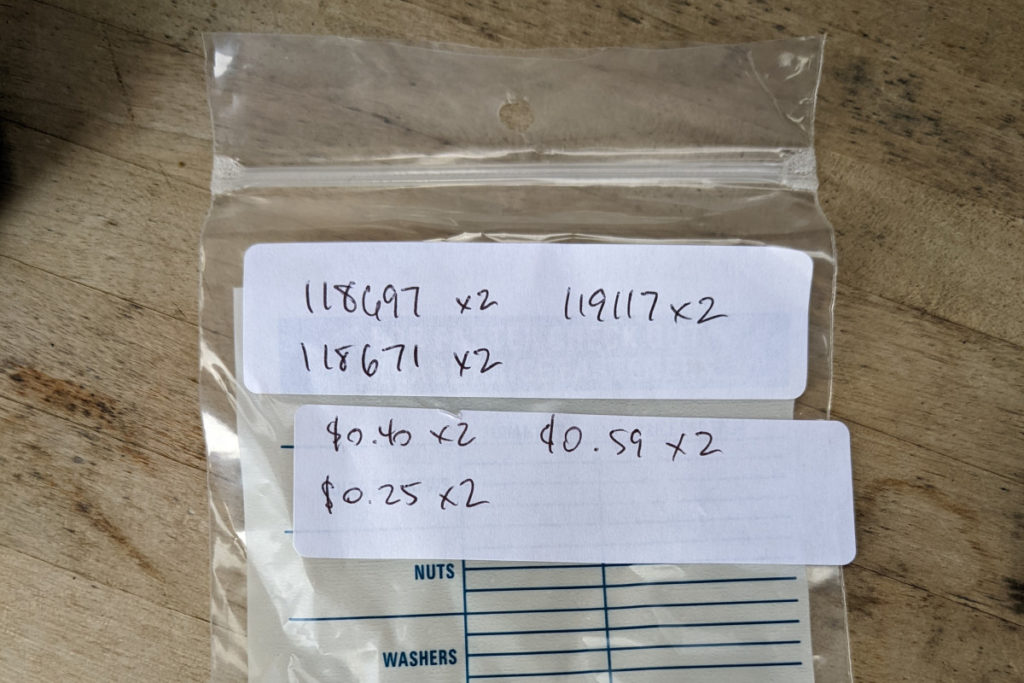

I put the parts into the provided baggie. They had labels out, so I wrote down the part numbers and quantities on a paper label instead of trying to get a ballpoint pen to write on a glossy plastic bag. I wandered around a bit and then took the parts up to the counter to check out. The guy looked at it for a full minute. He then peered over his glasses at the register screen and turned solemnly toward me.

“I…I don’t know how much these cost.”

“Oh, sorry, I’ll go get the prices,” I said, holding out my hand to take the bag back.

“It’s just that…I’m sorry.”

“Oh, it’s no problem. It’s my fault. I’ll go get you the prices.”

“I could…” his words drifted off as he turned to gaze toward the part bins. It was as if he was looking at a distant mountain peak, knowing that he’d have to climb it again to retrieve his climbing partner’s dead body.

I said, “It’s really no big deal. I know where I got them all. It will only take a minute,” as I carefully reached around the plexiglass barrier and took the bag out of his hand while he stood there, rapt.

I went back and got the prices. I used a second sticker with the full understanding that I might be introducing an insurmountable data-mapping error for the checkout guy—I was worried that trying to cram the prices into the available space on the first sticker could introduce a data-input error and I had to take a shot. I returned to the counter and handed it over, hoping for a quick resolution.

He squinted and massaged every square inch of the bag. He turned it over and examined it, trying to make sense of this artifact.

“It’s just…I don’t know, with the prices and the quantities…”

I could feel the hands on all the clocks in the world tick, tick, ticking. “There are six items there. Two at forty cents; two at twenty-five cents; two at fifty-nine cents.”

“But…the prices…”

“There are six items. Two at forty cents; two at twenty-five cents; two at fifty-nine cents.” I almost said “over” at the end, because by this point I was doing my impression of a pilot rotely reading numbers to air traffic control during a declared emergency.

“Hold on, wait, can you repeat that?”

I did. We got through it, despite him never gleaning any information from what I wrote on the bag.

I fought my way onto the Parkway and drove back to the marina. I tested the nuts and, surprise: they would not thread onto the studs. The entire trip to the store served no practical purpose.

They must be metric. I thought that they might be metric, since the engine is made in Japan and I had to use metric wrenches to get the old pump off, but it’s hard to tell with the stuff that’s been added on as part of the marinization process and there was nothing metric at the store to test it on. It sure seemed like it worked with a #12 bolt, but I guess that was a unidirectional coincidence. I used the old nuts. Having figured out the available angles to turn a wrench during the removal process, installing the new pump went smoothly. The clips that hold it on are far more robust than the originals. The old ones look like stamped and bent metal, whereas these appear to be machined. They’re taller than the originals, so there’s barely any room on the stud to get the nut on (and there would be less with a split washer), but it worked and feels sturdy.

I put the belt back on and tensioned it, then started the engine. Everything worked as expected.

This was the only major “unknown” that still needed to be addressed before we can start sailing. There are still a few minor maintenance items to check off, but it’s all routine. I’m going to change the oil again just to be absolutely sure that no water got into the engine from the blown seals on the pump, but I see no evidence of contamination (and from my time spent with a 1985 Ford Escort, I know what water in engine oil looks like).

We should be sailing soon.

I came dangerously close to buying a used sailboat a few years back. I enjoy reading your blog – it reaffirms the wisdom of my decision to forgo the purchase! Somewhere along the way, I came up with a mantra that seems to have withstood the test of time: “You can own a house, or a sailboat, but not both at the same time”.

Eh, I’m not known for my positivity, and the things that go wrong are usually funnier, but solving this kind of problem is still way more interesting to me than any home maintenance. I’m not really complaining. I can think of many worse ways to spend an afternoon than getting intimate with a 14hp diesel. Thanks for reading.