I suppose that by some standard, boat preparations for the season have begun. Although in that regard, my standards are pretty low.

I went down to the shore last weekend. It was kind of a snap decision, and it wasn’t terribly early in the afternoon when I left. I was concerned that I was forgetting basically everything, but I had a step ladder and marlinspike, and frankly didn’t want to deal with any problems that couldn’t be solved with those two items. The roads out of Philadelphia were clogged with approximately 900,000 other people who all apparently also made a snap decision to do anything other than binge-watch another 16 hours of whatever was on the top row of Netflix, so I wound up taking the less-than-ideal route to the shore, but as Mick Jagger repeatedly yelled, “Daylight saving time is on my side, yes it is.” Or something like that.

I first checked in at the marina office and tried to get a sense of where they were in their spring routine. They’re always pretty accommodating, but I try to go with the flow as much as possible. I have a vague fear that if I were to routinely top their shit list I’d be “up the creek,” which is a phrase that I coined to describe being banished to the Up the Creek Marina, next door. They seemed to be an ordinary amount of busy, so I scheduled a tentative time to launch.

I then proceeded to remove the cover. While putting the cover on is an oversized origami nightmare, taking it off is relatively easy, especially if there’s a breeze. Like Charlemagne said, “Let my armies be the wind and this marlinspike of dubious quality.” Actually he didn’t say that, and if you think I’m misquoting Sean Connery as Professor Henry Jones in the 1989 film Indiana Jones and the Last Crusade, Charlemagne didn’t say that either. But given enough wind, it truly is just a matter of untying all of the lines that hold the cover down, unzipping the zippers that go around the stanchions and shrouds, and letting it blow off—as a sailor, I feel like it’s my obligation to utilize the wind. This is what separates us from kayakers. Folding the cover, especially when solo, is another matter, so I “folded” it (with the quotes), jammed it into the back of my car, and took the scenic route home through the woods.

Another outstanding preparation item is refinishing my tiller. In the last log entry, I was worried that I might not be able to resist the temptation to give it a rattle can glitter job, since I know how to do that now and suddenly want everything to look like the tiara aisle in a Claire’s. I managed to go with a more traditional varnish, but may be regretting it.

When Roos sneakers and Z. Cavaricci jeans were popular, I had Kangas and N. Cavaluccis, and I have often wondered if this is why I can get a little fixated on “quality products.” It’s not for everything. Like I don’t require the Patek Philippe of laundry detergents, for example. My canvas sewing machine is a Reliable Barracuda, which was definitely a “value” purchase. I wonder if I should have held out for the Sailrite, but I don’t really sew that much. I own some tools from the China’s Cheapest Objects store, although any purchase there usually involves some calculus including “When this disintegrates at full speed, will it take my hand off?” I also own some really nice tools, for when I want to use them forever, want them to be precise, or will have to touch them a lot. For years and years, I would only wear outerwear made by Filson, whose motto is specifically “Might as well have the best,” but they’ve gone from selling Seattle-made mining outfits from the Klondike Gold Rush to nylon bookbags and $100 Popeye Pint glasses and I don’t even know what to do with myself. If I ever need another jacket, I’m going to have to find some 19th century tarpaulins and make my own with my Reliable Barracuda. I want to find a reasonable middle ground of value and quality, but tend to mess this up in both directions.

For my tiller varnish, I decided to go with Epifanes. It’s supposed to be among the best (at least for looks; Practical Sailor wasn’t overwhelmed with its technical performance). This varnish is so fancy, I can’t even identify the languages on the label. I’m guessing that it may be a mix of French and Dutch, but the bulk of my French education is from the blowback I received when trying to order un grand deux-deux from a Tim Horton’s on the outskirts of Quebec City (which did not include any spar varnish vocabulary), and my knowledge of Dutch is substantially less than that. Perhaps the only varnish that I’ve seen people gush about as much is Le Tonkinois, which appears to come in a Spam can decorated with some Asian motifs that probably made more sense 75 years ago. I drew the line at “free 2-day shipping” and went with Epifanes.

The first step was to remove the old varnish. I was originally hoping that I could get by with a re-coat, but the aft end of the tiller was all messed up. When the traveler is centered (and it’s often centered when I’m having a lazy sail) my mainsheet block can hit the tiller if the sheet isn’t taut, and apparently has, hundreds of times.

The old finish came off easily with a heat gun and scraper. I then sanded out the damage and lightly sanded the whole thing to prep it. I thought that I’d used Epifanes on this last time, but I remembered what the can looked like, and an image search reminded me that it was actually Pettit Flagship. I definitely would have remembered using Epifanes, because it is the consistency of honey and dries much more slowly.

The official finishing schedule calls for it to be thinned 50% with mineral spirits, applied with a brush, and left for 24 hours to dry. Then it must be sanded with 220 grit sandpaper and a second coat applied, thinned with 25% mineral spirits. After 24 more hours, that can be sanded with 280 and a third coat can be applied, thinned with 15% mineral spirits. Another 24 hours, final sanding, then FOUR MORE COATS with 0-5% thinner at one day each.

This is absurd to me. 220 seems way too aggressive. I’m not sure that 280 is even a grit. And the whole thing is supposed to take a full week? In practice, it doesn’t even really dry after 24 hours. That’s supposedly at 64°F, which isn’t far off of what my basement is. Maybe it’s a tiny bit colder in the shop, but not a ton. I’ve been having to wait more like 36 hours, and since that occasionally occurs at dumb times it’s sometimes been more like 48 hours between coats. I’ve taken to bringing it over to my music nook, where it is slightly warmer, to try to get the varnish to kick. It really adds to the décor.

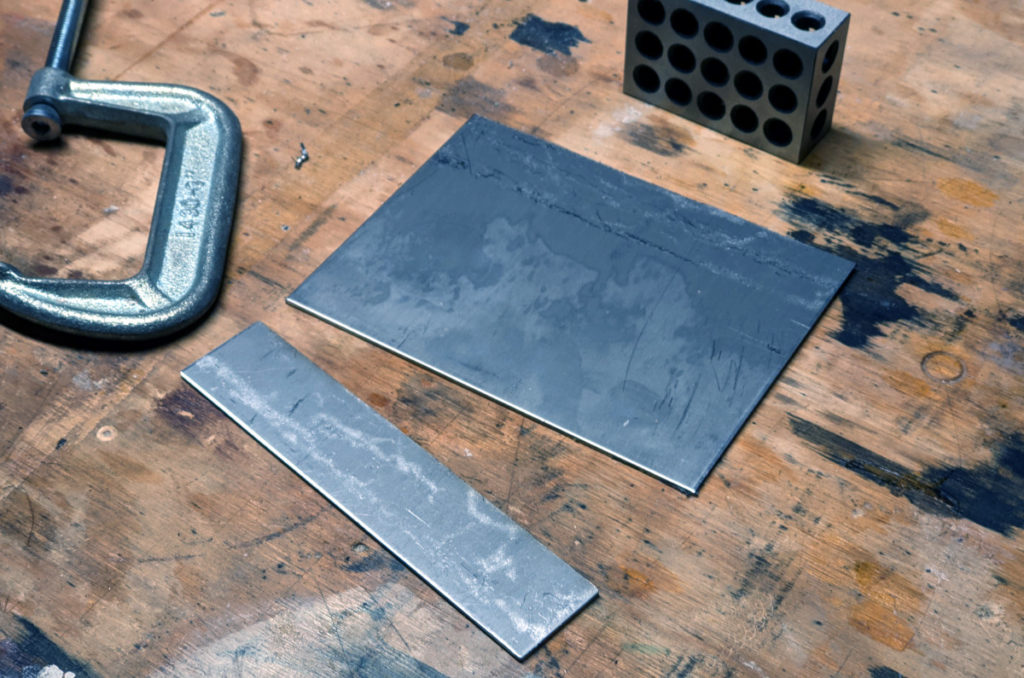

In order to prevent it from getting mangled in the future, I am also making a small steel plate for the aft end of it. My ability to work with steel is pretty limited, but my China’s Cheapest Objects® brand jigsaw fitted with a hacksaw blade did eventually gum through it.

My countersink bit can apparently be used exactly four times on stainless. It got pretty eaten up in the process, but made it just far enough.

I could theoretically paint the bottom this upcoming weekend (weather permitting) and launch next week, although at this point it’s a race to see if I can get a sufficient amount of varnish on the tiller. I don’t want to skimp on it, because I spend a lot of time handling the tiller and don’t want the finish to flake off immediately, but unless I can get the time between coats down to an honest 24 hours, it’s going to push me back at least an entire week. I am now feeling like maybe I was a little unprepared for these preparations, but I’ll get there.