Even with the late start to the sailing season, I got my spring maintenance tasks in while it was still technically spring. Very late spring.

I am a generally scientifically-minded person. If asked—say, as part of a test of my own sanity—I would be quick to admit that the engine in my boat is merely a machine, lacking consciousness or an immortal soul. However, when I talk about my engine I often find myself using phrases like “it needs this,” or “it wants that,” or “it is happiest when I…” This is the only diesel engine I’ve ever known, and between my lack of understanding of how it works and the fact that its behavior is so quirky and non-deterministic to me, it’s easy to slip into personifying language. I imagine that my relationship with it is not unlike an ancient culture’s relationship to a nearby simmering volcano. All you know is that you don’t want it to blow up, and if you do a certain dance or toss a virgin into it and it doesn’t blow up, you connect the dots and consider it sufficiently appeased.

Despite this reverence, I also probably don’t actually do enough to keep it in the best shape. I’ve never felt good about posting pictures of it, because I’m sure that someone is going to look at them and find me a neglectful steward. Yeah, the water pump is green with corrosion, the paint’s coming off the alternator, there’s belt dust all over everything that could possibly accumulate belt dust, and the engine bay is a mess. But whatever. Like Eminem at the end of 8 Mile, I’m just going to own it and “mom’s spaghetti” this mom’s spaghetti.

Of the six screws that hold the cover on my raw water pump, one has had its head broken off. I didn’t do it…it came like that. It bothers me for several minutes a year, and then I remind myself that it doesn’t leak. If I were to try to go after it with a screw extractor or something, I’d probably manage to mar the mating surface and make it worse. So I embrace the wabi sabi. It is imperfect. It is impermanent. It still pumps water just fine.

I did change the impeller though, because it is a disposable piece of rubber and does not improve with age.

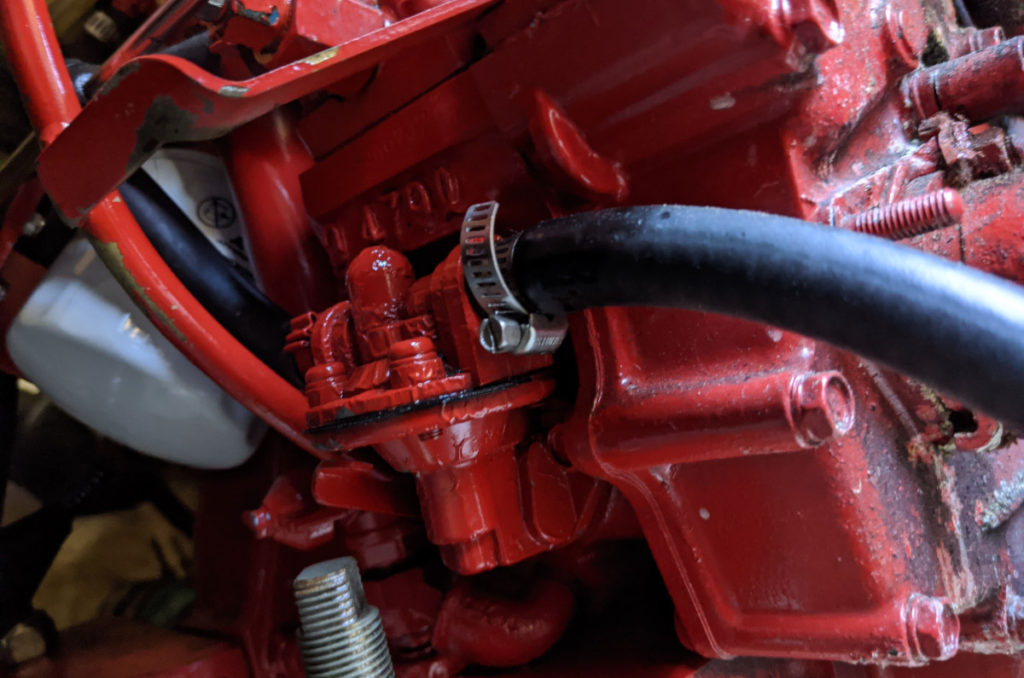

I also changed the fuel filters. My engine has two, an outboard Racor just after the fuel tank and one that looks like an oil filter that screws directly to the engine in a location mostly inaccessible to human hands. The Racor is very straightforward to change. Its lid is held on with a bronze T-handle that requires no tools to remove, and once it’s off, the filter element pops right out. The replacement element comes with new O-rings for the handle and the lid, and it all goes back together with no problem. The on-engine filter is trickier to get to, since it’s not sitting out in the open of a compartment. I constructed a small diesel dam to stop any fuel from getting into my bilge, and tried to reach around the engine to get to it. In the past, I’ve had to resort to multiple kinds of filter wrenches to get it started (none of which actually fit in the available space), even though it’s only ever hand-tightened when it’s installed, but I was able to unscrew it by hand this year after only several minutes of attempting to turn it the wrong way. “Lefty loosey” apparently falls apart for me when rotated 90° and done blindly with my left hand, to the point where I had to pantomime it with my right hand and manually show my left hand how to do it. But I was rewarded with a gush of diesel as the seal was broken, and I quickly unscrewed it the rest of the way, fished it out, and tossed it into a receptacle that Jenn had prepared. She then handed me paper towels like a surgical nurse so that I could tidy the area and shore up the dam.

My least favorite aspect of changing the fuel filters is that the process introduces air into the fuel system which needs to be bled before the engine will operate correctly. Don Casey’s This Old Boat describes it like this:

Why does air in the fuel lines prevent a diesel engine from running? Because the injection pump essentially hammers a column of “solid” fuel against a check valve in the injector that “pops” open when the pressure reaches a preset level. But if you put an air bubble in the line, the bubble acts like a spring between the pump and in the injector. It compresses, and the pressure at the injector never rises to the level needed to pop the valve. No fuel reaches the cylinder.

I am certain that this is accurate, but I could also imagine Geordi La Forge excitedly explaining it to Captain Picard before suggesting that they solve it by reversing the polarity of the bussard collector, thereby nullifying the tachyon field. Personally, I am content to know that the guy who sold me the boat showed me the magic bolt to partially unscrew and the tiny little tab that theoretically manually operates the fuel lift pump to bleed the engine.

Regardless of my deep knowledge of both the magic bolt and the tiny little tab, I have never successfully bled the engine on the first try. I’ll get it to the point where it will start, and it will run indefinitely at the dock, but then as soon as I try to do something crazy like “use the engine to propel the boat,” it will quit. It was getting kind of late for a sail, but after 10,000 pumps of the tiny little tab and a lot of effort from the starter, I wanted to go for a short motorboat ride just to make sure that it was really working.

Jenn and I threw off the lines. I put the engine into reverse, thinking “this is when it’s going to stop.” It didn’t. I backed out of the slip and put the transmission into forward, thinking “ok, this is when it’s going to stop,” but it also didn’t. We motored out of the marina and I thought, “Oh, here we go,” as I looked ahead and saw that the buoys marking the entrance to the channel had been rearranged into a completely nonsensical configuration.

The engine continued chugging along though, and I was able to figure out which buoys were the ones that were actually supposed to be there. We drove all the way to the end of the creek before turning around and heading back. I guess someone was coming in and hit buoy #8, and then dragged it 4,000 feet or so before depositing it near #13.

In some ways, I wish the engine would have quit, because then I’d be more confident that it got its tantrum out of the way and that I was in the clear. I suppose it’s also possible that my (late) spring maintenance was just successful, and that engines do not throw tantrums or actively conspire against me. But it’s more likely that I just did a better job with the ceremony and that the engine has been sufficiently appeased.

Been awhile since I’ve been to my boat. I need to get back at it.

Hey Daniel, good to hear from you. Hope you get some sailing in soon.